Unlocking Precision: The Role of a **CNC Machining Company** in Modern Manufacturing

In today's rapidly evolving industrial landscape, the demand for precision and efficiency in manufacturing processes is more critical than ever. This is where the expertise of a CNC machining company comes into play. At DeepMould.net, we specialize in providing top-notch CNC machining services that cater to a variety of industries, all while ensuring unparalleled quality and precision in every project.

What is CNC Machining?

CNC, or Computer Numerical Control, machining refers to the automated process of using computer software to control the movement of machinery and tools. This technology enables the production of complex components with a high degree of accuracy and repeatability. It is widely employed across various sectors, including aerospace, automotive, and medical devices.

The Advantages of Choosing a Professional CNC Machining Company

- Precision and Accuracy: One of the foremost advantages of CNC machining is that it produces parts with minimal tolerances, ensuring a perfect fit in assembly and operation.

- Efficiency: CNC machines can run continuously, allowing for high production rates and quicker turnaround times.

- Complex Design Capability: CNC machining enables the creation of intricate designs that would be challenging or impossible to achieve using traditional manufacturing methods.

- Cost-Effectiveness: While initial setup costs may be high, the long-term savings from reduced waste and increased productivity often outweigh these costs.

- Versatility: A CNC machining company can work with a variety of materials, including metals, plastics, and composites, providing a wide range of solutions for different applications.

Types of CNC Machining Services Offered by DeepMould.net

At DeepMould.net, we provide a comprehensive range of CNC machining services tailored to meet the unique needs of our clients:

1. CNC Milling

CNC milling involves the use of rotating cutting tools to remove material from a workpiece. Our state-of-the-art milling machines allow us to create precise components with complex geometries. This service is ideal for producing parts such as brackets, housings, and custom prototypes.

2. CNC Turning

In CNC turning, the workpiece rotates while a stationary cutting tool shapes it. This process is perfect for producing cylindrical components, including shafts, bushings, and fittings. Our advanced lathes guarantee high precision and quality in every turn.

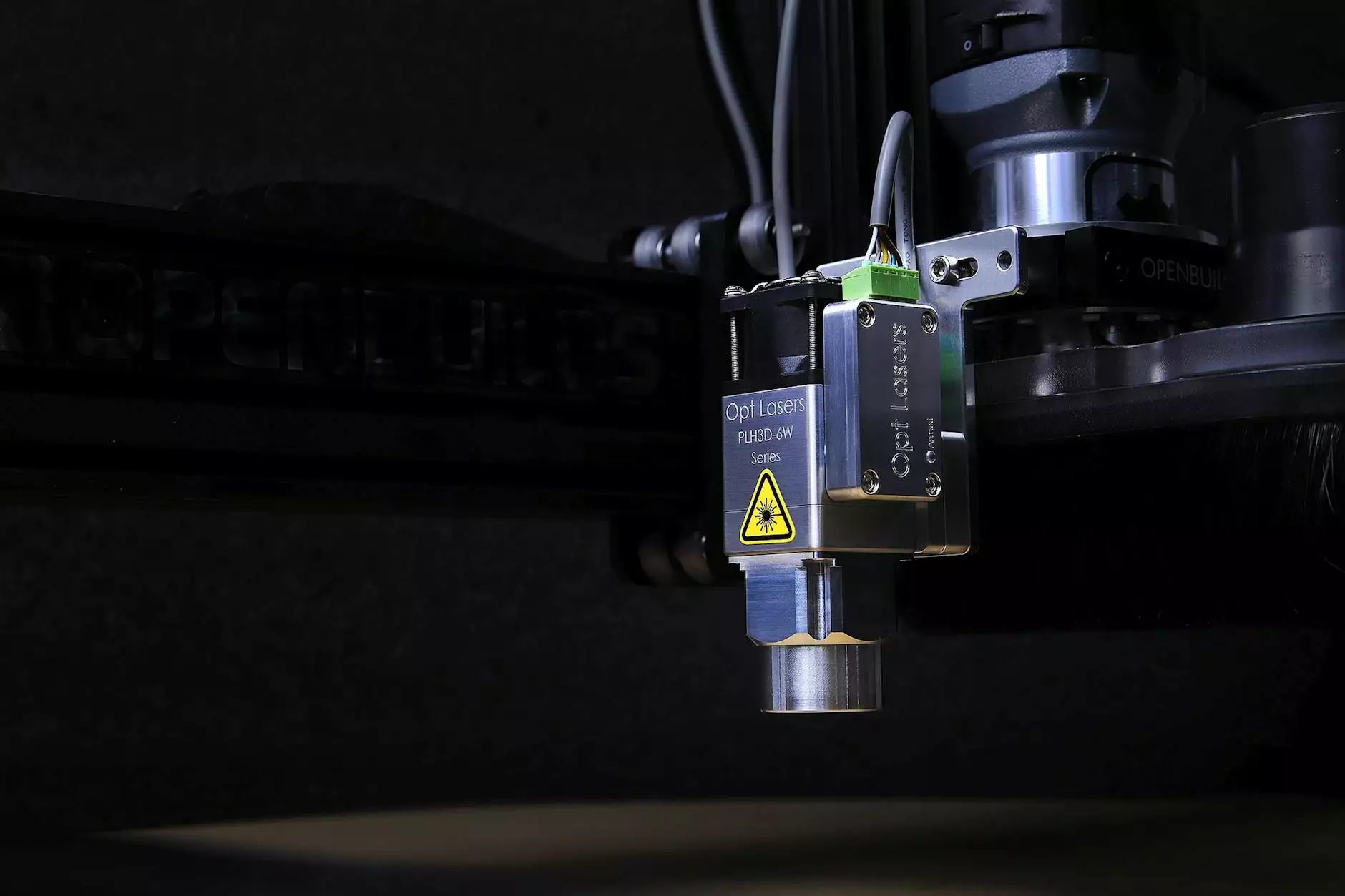

3. CNC Laser Cutting

Utilizing high-powered lasers, CNC laser cutting provides exceptional accuracy for cutting intricate patterns and designs. This method is ideal for sheet metal fabrication, allowing us to achieve clean edges and tight tolerances.

4. CNC Wire EDM

Electrical Discharge Machining (EDM) employs a wire electrode to cut through conductive materials. This technique is beneficial for creating complex shapes and precise features in harder metals, making it invaluable for tool and die makers.

Industries That Benefit from CNC Machining

The versatility of CNC machining allows it to serve a wide range of industries. Here is a brief overview of some sectors that rely heavily on the services of a CNC machining company:

- Aerospace: Aerospace components require extreme precision and adherence to strict regulations, making CNC machining an ideal solution.

- Automotive: From prototype development to high-volume production, CNC machining is integral to automotive manufacturing.

- Medical: The medical industry demands components with high purity and precision, fitting the unique requirements of equipment and devices.

- Electronics: CNC machining facilitates the production of thin, intricate parts crucial for modern electronic devices.

- Defense: Military applications require robust and reliable parts that can withstand harsh conditions, making CNC machining essential.

How to Select the Right CNC Machining Company

Choosing the right CNC machining service provider is crucial for ensuring quality and reliability. Here are some factors to consider:

- Experience: Look for a company with a strong track record in CNC machining and relevant industry experience.

- Technology: Ensure the company utilizes modern machinery and software to maintain competitive advantages in production and design.

- Certifications: Certifications such as ISO 9001 indicate a commitment to quality management and continuous improvement.

- Customer Support: A responsive customer service team will help address your concerns and enhance your overall experience.

- Flexibility: The ideal CNC machining company should be able to accommodate both large production runs and custom, low-volume projects.

Understanding the CNC Machining Process

The CNC machining process typically involves several key steps:

Step 1: Design Creation

The process begins with a detailed design, often created using CAD (Computer-Aided Design) software. This design is crucial as it dictates the final dimensions and features of the part.

Step 2: Toolpath Generation

Once the design is complete, CAM (Computer-Aided Manufacturing) software generates a toolpath. This specifies the movement of the CNC machine, ensuring accurate manufacturing based on the designed specifications.

Step 3: Machine Setup

The CNC machine is prepared for production, which includes the installation of the necessary tools and material. A skilled technician is essential in this step to ensure everything is aligned perfectly.

Step 4: Machining

The machining process begins, with the CNC machine executing the programmed instructions to produce the component. Continuous monitoring allows for adjustments to maximize accuracy.

Step 5: Quality Control

Every part produced goes through rigorous quality control measures. This ensures that it meets all necessary specifications and tolerances before it is shipped to the client.

Embracing the Future of CNC Machining

The CNC machining industry is on the brink of a technological revolution, driven by advancements in automation, artificial intelligence, and material science. Companies like DeepMould.net are embracing these changes to remain at the forefront of manufacturing innovation.

Automation in CNC Machining

With automation becoming more prevalent, CNC machines are increasingly equipped with robotics that allow for fully automated production lines. This not only enhances the speed of production but also reduces the potential for human error.

Integration of AI and Machine Learning

Machine learning algorithms can optimize machining processes by predicting issues before they arise and adjusting operations accordingly. This leads to improved efficiency and lower operational costs.

Advancements in Material Science

As new materials are developed, CNC machining can adapt to meet the challenges they present, offering even greater versatility in production capabilities. This includes the use of lightweight composites and advanced alloys that demand precision machining techniques.

Conclusion

In conclusion, selecting a reliable CNC machining company like DeepMould.net is crucial for ensuring high-quality and precise manufacturing. With advanced technology, a commitment to excellence, and a broad range of services, we are well-equipped to meet the diverse needs of industries today and into the future.

To learn more about our CNC machining services and how we can help your business achieve its manufacturing goals, visit us at DeepMould.net.